Poly-V Pulley

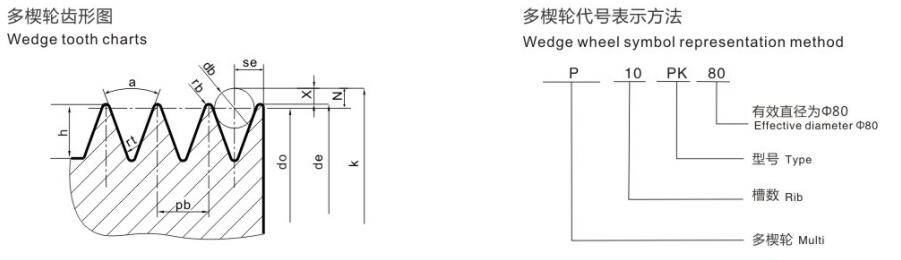

Multi-wedge pulley is a transmission element with multiple wedge grooves. The transmission efficiency and load-bearing capacity are improved by increasing the number of wedge grooves. Its working principle is based on the extrusion effect of the wedge groove. When the belt moves in the wedge groove, the wedge shape of the groove causes the belt to be radially squeezed, thereby generating greater friction, allowing the belt to fit more closely on the pulley, reducing slippage and energy loss, and improving transmission efficiency

Contact Us

Contact Us

Return To The Previous Page

Return To The Previous Page

Located by the affluent and beautiful Hangzhou Bay, our company enjoys a scenic location with mountains and water, and a talented workforce. The old factory is situated along the 329 National Road in Longshan Town, while the new factory is conveniently located in the Longshan Industrial Park by the sea. In the past twenty years, through the hard work and innovation of our dedicated employees, we have established strong cooperative relationships with nearly a thousand clients in China and are expanding into international markets. Our company is equipped with advanced machinery, standardized manufacturing processes, comprehensive testing equipment, and strict enterprise management. Our technical management team, which includes some of the earliest developers of synchronous belt transmission products in China, boasts a wealth of professional experience. We have obtained ISO 9001:2000 certification, ensuring the quality of our products, which are widely used and recognized by clients in various industries both domestically and internationally, earning a good reputation for the "Slongwang" brand.

Our products are extensively used in various industries, including machine tools, textiles, printing, food packaging, home appliances, engraving, wire and cable, instruments, petrochemicals, tobacco, and communications, for the transmission of new mechanical drives.

Adhering to the traditional virtues of "sincerity, honesty, and earnestness," Slongwang advocates for high-quality and affordable products to achieve a win-win situation. We strive to lead the market with reliable products, more favorable prices, and faster delivery times, aiming to attract a broader range of partners. With a vision to establish a strong and large enterprise that stands the test of time, we are committed to creating a century-old business. We are eager to work with visionaries worldwide to forge a brilliant future.

Synchronous pulley consists of a circular belt with evenly spaced teeth on its inner circumference and a correspondingly engaging pulley. It combines the advantages of belt drives, chain drives, and gear drives. During transmission, power is transferred through the meshing of the belt teeth with the pulley's tooth grooves.

Synchronous pulley offers precise transmission ratios, no slippage, and constant speed ratios, ensuring smooth operation, vibration absorption, low noise, a wide range of transmission ratios (up to 1:10), and allowable linear speeds of up to 50 m/s. It can transmit power from a few watts to hundreds of kilowatts. With high transmission efficiency, generally reaching 98%, it is compact, suitable for multi-shaft transmission, and requires no lubrication, making it pollution-free and ideal for environments where contamination is not allowed or where working conditions are harsh.

-

Feb 04,2026In modern manufacturing environments, efficiency and stability are key factors that influence productivity. Production l...Read More

-

Jan 28,2026In modern industrial operations, efficiency, reliability, and cost-effectiveness are paramount. Industrial equipment suc...Read More

-

Jan 21,2026In the world of construction and heavy machinery, efficiency, durability, and reliability are paramount. From excavators...Read More

-

Jan 14,2026In today’s fast-paced industrial environment, the demand for higher efficiency, reliability, and precision in manufactur...Read More

Advantages and applications of poly-V belt pulleys: improving transmission efficiency

The poly-V belt pulley is a highly efficient transmission element widely used in modern industrial transmission systems. It improves the transmission efficiency and load-bearing capacity through the design structure of multiple wedge grooves, and has become an indispensable part of many high-load and high-efficiency mechanical equipment. Ningbo Slongwang Synchronous Belt Co,.Ltd., as one of China's leading manufacturers of synchronous belts and belt transmission products, produces poly-V belt pulleys that not only meet international standards, but also provide a variety of specifications and models, which are widely used in different industrial fields.

The working principle of the poly-V belt pulley is based on the extrusion effect of the wedge groove. Compared with the traditional V-belt pulley, the multiple wedge grooves of the poly-V belt pulley can provide a larger contact area, thereby achieving more efficient transmission. Each wedge groove can generate additional friction when driving the belt to run, so that the belt fits more closely on the pulley surface, reducing slippage and improving transmission efficiency. This design can not only ensure higher load capacity, but also significantly reduce energy loss and increase the operating stability of the equipment.

The poly-V belt pulley can improve transmission efficiency. Due to the presence of multiple wedge grooves, the contact area between the pulley and the belt is wider than that of the traditional V-belt pulley, thereby increasing friction and reducing slippage. This increased friction enables the poly-V belt pulley to better transmit power and ensure efficient mechanical operation. The poly-V belt pulleys produced by Ningbo Slongwang are reasonably designed to withstand greater loads, allowing the transmission system to operate stably under high load and high power environments, and are particularly suitable for industrial automation, mining equipment, agricultural machinery and other fields.

The poly-V belt pulley has a strong load-bearing capacity. Traditional V-belt pulleys usually have only one contact surface, so their load-bearing capacity is limited to a certain extent. The poly-V belt pulley shares the load during the transmission process through the design of multiple wedge grooves, thereby improving the overall load-bearing capacity. Especially in some application scenarios with high load requirements, such as lifting machinery, mining transportation equipment, etc., poly-V belt pulleys can provide stronger support and stability.

Ningbo Slongwang's poly-V belt pulleys also have strong wear resistance and environmental resistance. This allows them to operate for a long time in various harsh environments. For example, in complex working environments such as chemical plants, metallurgical plants, and mines, pulleys need to withstand harsh conditions such as high temperature, high humidity, and chemical corrosion. The poly-V belt pulley is made of high-strength materials and has undergone precise processing to maintain a long service life under these conditions. This environmental resistance reduces the frequency of maintenance for industrial equipment and reduces long-term operating costs.

The compact design of the poly-V belt pulley is also a major advantage. Traditional V-belt pulleys usually require a large space to accommodate the belt and pulley, while the poly-V belt pulley can achieve more efficient transmission in a smaller space due to its special multi-V groove structure. For applications that need to save space or require highly integrated equipment, the poly-V belt pulley provides a more suitable solution.

Compared with traditional V-belt pulleys, poly-V belt pulleys also have better adjustment performance. During the installation and adjustment of the transmission system, the poly-V belt pulley can cooperate with the multi-V belt more accurately, thereby achieving higher transmission accuracy and stability. Especially in some mechanical equipment with higher requirements, the precise transmission performance can effectively avoid errors caused by transmission errors in the equipment and ensure the efficient operation of the entire production line.

The poly-V belt pulley series products produced by Ningbo Slongwang cover different specifications and models, which can meet the needs of various industrial equipment. Whether in high-power, high-load applications or in equipment with limited space and high precision requirements, poly-V belt pulleys can provide suitable transmission solutions. By reasonably selecting the appropriate pulley and belt combination, users can significantly improve the working efficiency of the equipment, extend its service life, and reduce maintenance costs.

How to improve the working efficiency of mechanical equipment by using poly-V belt pulley

Ningbo Slongwang Synchronous Belt Co., Ltd., as a leading synchronous belt manufacturer in China, provides a variety of high-performance belt drive products, including poly-V belt pulleys. With its good design and high-efficiency transmission characteristics, poly-V belt pulleys play a vital role in improving the working efficiency of mechanical equipment. Multi-V belt pulleys are a mechanical element that improves transmission efficiency and load-bearing capacity through multiple wedge groove structures. Compared with traditional V-belt pulleys, poly-V belt pulleys have multiple wedge grooves in their structure, which can increase the contact surface between the belt and the pulley and further enhance the friction. In this way, when the belt moves through the wedge grooves, it can transmit power more effectively, reduce energy loss, and reduce the risk of belt slippage.

Improve transmission efficiency Multi-V belt pulleys can significantly improve the efficiency of power transmission by increasing the number of wedge grooves and optimizing the design. Since each wedge groove can transmit power independently, the belt is evenly distributed in multiple wedge grooves, reducing the burden on a single wedge groove. In this way, not only can more power be transmitted, but also more uniform friction can be ensured during the transmission process, thereby reducing power loss and system wear, ensuring higher working efficiency.

In industrial production, the operating efficiency of equipment directly affects the overall production capacity and energy consumption. By using poly-V belt pulleys, mechanical equipment can be more stable during operation, power transmission is more accurate, which helps save energy, reduce the frequency of equipment failures and extend the service life of equipment. The poly-V belt pulleys provided by Ningbo Slongwang Synchronous Belt Co,.Ltd. perform well in this regard, and can cope with high-load transmission requirements under various complex working conditions.

Load-bearing capacity and environmental resistance Multi-V belt pulleys use high-quality materials and precision processing technology and have high load-bearing capacity. Since each wedge groove shares the transmission load, the pressure of a single contact point is reduced, allowing the poly-V belt pulley to transmit greater power in a smaller space. Therefore, in situations where high power transmission and long-term operation are required, the use of poly-V belt pulleys can improve the working efficiency of mechanical equipment.

The materials used in the poly-V belt pulleys of Ningbo Slongwang Synchronous Belt Co,.Ltd. have the characteristics of temperature resistance, oil resistance, and corrosion resistance. Even in harsh industrial environments, the pulleys can still maintain excellent performance. The stability of the poly-V belt pulley enables the equipment to operate efficiently and stably even in extreme environments such as high load, low temperature or high temperature, thereby reducing downtime or equipment damage caused by environmental factors.

Smooth operation and reduced vibration The poly-V belt pulley can achieve a smoother working state by uniform force and reduced belt slip during operation. This not only improves the working efficiency of mechanical equipment, but also reduces vibration and noise, thereby reducing the impact on the operating environment. In high-speed equipment, excessive vibration will not only cause additional load on the equipment, but may also cause structural damage. By using the poly-V belt pulley produced by Ningbo Slongwang, the smooth operation of the equipment has been improved and the risk of failure caused by vibration has been reduced.

Optimize equipment design and reduce maintenance costs Compared with traditional pulleys, equipment using poly-V belt pulleys usually has a more compact design. This design can provide higher power transmission capacity in the same space and adapt to higher transmission requirements. In addition, due to the high efficiency of the poly-V belt pulley, the equipment is subjected to less stress and wear during operation, reducing the frequency of maintenance and replacement of pulleys and reducing the long-term maintenance cost of the equipment.

By rationally selecting efficient poly-V belt pulleys, enterprises can not only improve the working efficiency of mechanical equipment, but also optimize production processes, reduce failure rates and maintenance costs. In today's increasingly competitive market, improving the efficiency of mechanical equipment often means lower energy consumption, higher production capacity and longer service life, all of which directly affect the competitiveness of enterprises.

English

English 中文简体

中文简体