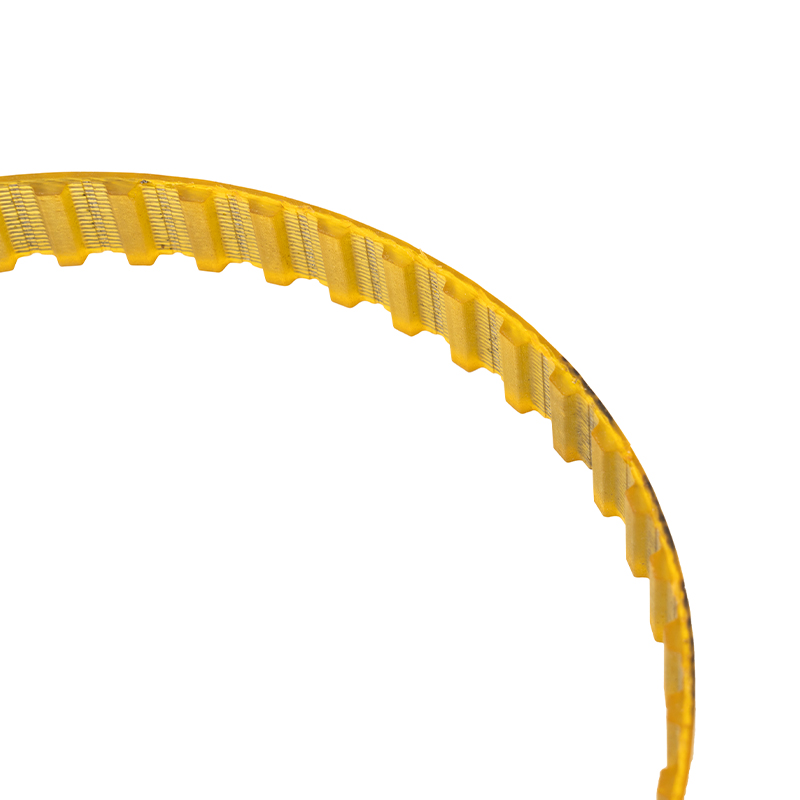

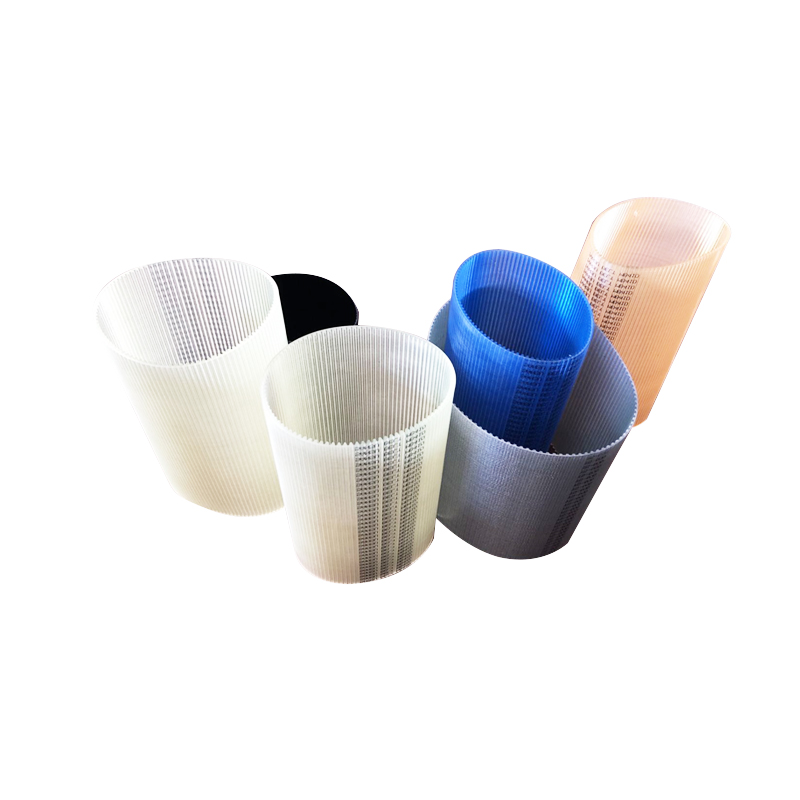

Polyurethane Synchronous Belt

Polyurethane synchronous belt is a transmission belt made of polyurethane material and thermoplastic by barrel mold. It achieves precise transmission by meshing with the timing pulley. It has the characteristics of high precision, low noise, wear resistance, resistance to oil and chemical corrosion, and lightweight design.

Contact Us

Contact Us

Return To The Previous Page

Return To The Previous Page

Located by the affluent and beautiful Hangzhou Bay, our company enjoys a scenic location with mountains and water, and a talented workforce. The old factory is situated along the 329 National Road in Longshan Town, while the new factory is conveniently located in the Longshan Industrial Park by the sea. In the past twenty years, through the hard work and innovation of our dedicated employees, we have established strong cooperative relationships with nearly a thousand clients in China and are expanding into international markets. Our company is equipped with advanced machinery, standardized manufacturing processes, comprehensive testing equipment, and strict enterprise management. Our technical management team, which includes some of the earliest developers of synchronous belt transmission products in China, boasts a wealth of professional experience. We have obtained ISO 9001:2000 certification, ensuring the quality of our products, which are widely used and recognized by clients in various industries both domestically and internationally, earning a good reputation for the "Slongwang" brand.

Our products are extensively used in various industries, including machine tools, textiles, printing, food packaging, home appliances, engraving, wire and cable, instruments, petrochemicals, tobacco, and communications, for the transmission of new mechanical drives.

Adhering to the traditional virtues of "sincerity, honesty, and earnestness," Slongwang advocates for high-quality and affordable products to achieve a win-win situation. We strive to lead the market with reliable products, more favorable prices, and faster delivery times, aiming to attract a broader range of partners. With a vision to establish a strong and large enterprise that stands the test of time, we are committed to creating a century-old business. We are eager to work with visionaries worldwide to forge a brilliant future.

Synchronous pulley consists of a circular belt with evenly spaced teeth on its inner circumference and a correspondingly engaging pulley. It combines the advantages of belt drives, chain drives, and gear drives. During transmission, power is transferred through the meshing of the belt teeth with the pulley's tooth grooves.

Synchronous pulley offers precise transmission ratios, no slippage, and constant speed ratios, ensuring smooth operation, vibration absorption, low noise, a wide range of transmission ratios (up to 1:10), and allowable linear speeds of up to 50 m/s. It can transmit power from a few watts to hundreds of kilowatts. With high transmission efficiency, generally reaching 98%, it is compact, suitable for multi-shaft transmission, and requires no lubrication, making it pollution-free and ideal for environments where contamination is not allowed or where working conditions are harsh.

-

Feb 04,2026In modern manufacturing environments, efficiency and stability are key factors that influence productivity. Production l...Read More

-

Jan 28,2026In modern industrial operations, efficiency, reliability, and cost-effectiveness are paramount. Industrial equipment suc...Read More

-

Jan 21,2026In the world of construction and heavy machinery, efficiency, durability, and reliability are paramount. From excavators...Read More

-

Jan 14,2026In today’s fast-paced industrial environment, the demand for higher efficiency, reliability, and precision in manufactur...Read More

Advantages of polyurethane synchronous belts in high-load environments

Polyurethane synchronous belts are an important component widely used in precision transmission systems. They are increasingly favored by the industry because they can provide efficient and stable transmission effects in a variety of high-demand environments. Ningbo Slongwang Synchronous Belt Co., Ltd. is a leading synchronous belt manufacturer in China, focusing on producing synchronous belts and related transmission products that meet international standards. The company provides a variety of synchronous belt solutions, including polyurethane synchronous belts. Polyurethane synchronous belts are made of thermoplastic polyurethane materials and have many advantages, which have made them widely used in many fields.

One of the characteristics of polyurethane synchronous belts is their extremely high precision. It ensures efficient cooperation of various components in the mechanical system through precise engagement with the synchronous pulley. Synchronous belts transmit power to achieve precise linear or rotational motion, which is essential for equipment that requires high-precision transmission. Whether it is CNC machine tools, precision instruments, or automated production lines, polyurethane synchronous belts can provide precise control, reduce mechanical errors, and improve the stability of equipment operation.

During the transmission process, polyurethane synchronous belts have low noise, which greatly improves the comfort of the working environment. Compared with traditional rubber timing belts, the high-density structure of polyurethane materials helps reduce the noise generated during high-speed operation, avoiding discomfort in the working environment or mechanical wear caused by noise problems.

Wear resistance is another major advantage of polyurethane synchronous belts. The polyurethane material it uses has extremely strong wear resistance, especially suitable for use in high-load, long-term operation environments. In many industrial applications, the transmission belt needs to withstand large mechanical loads, and long-term friction and movement will cause wear of the belt. The wear resistance of polyurethane materials allows polyurethane synchronous belts to maintain a long service life under these conditions, reducing the cost of frequent replacement and the risk of production interruptions.

The oil resistance and chemical corrosion resistance of polyurethane synchronous belts enable them to work stably in some harsh environments. In many industrial applications, substances such as oil, chemical liquids or gases may come into contact with the transmission belt and cause damage. Polyurethane materials have strong oil and corrosion resistance, which can effectively resist the erosion of these harmful substances, thereby extending the service life of the timing belt and ensuring long-term and efficient operation of the equipment.

Lightweight design is another advantage of polyurethane synchronous belts. Compared with other types of timing belts, polyurethane synchronous belts are lighter, which helps to reduce the load of the system and improve the overall energy efficiency of the equipment. Lightweight design is particularly suitable for some equipment that requires lighter weight, such as precision instruments, automated robots, etc. In these applications, lightweight timing belts not only help improve transmission efficiency, but also reduce energy consumption and equipment burden.

In practical applications, the polyurethane synchronous belts provided by Ningbo Slongwang Synchronous Belt Co., Ltd. are widely used in automation equipment, CNC machine tools, food processing equipment, precision instruments and other industries. Especially in industrial environments that require long-term stability and high precision, polyurethane synchronous belts meet the high requirements of more and more customers for transmission belt performance with their unique material advantages.

As a leading manufacturer in the synchronous belt industry, Ningbo Slongwang Synchronous Belt Co., Ltd. has always been committed to providing customers with high-quality synchronous belt products. With many years of experience and advanced production technology, the company produces polyurethane synchronous belts that meet international standards to meet the needs of various industries. The company's products cover multiple fields, including rubber timing belts, PU timing belts, double-sided tooth timing belts, etc., and can provide customers with one-stop transmission solutions.

How polyurethane synchronous belts can improve the performance of industrial equipment

Polyurethane synchronous belts are widely used transmission components in industrial equipment. Due to their good physical and chemical properties, they are particularly suitable for high-load and high-precision transmission systems. Ningbo Slongwang Synchronous Belt Co,.Ltd., as a leading synchronous belt manufacturer in China, produces and supplies a variety of synchronous belts, including polyurethane synchronous belts. The company focuses on providing high-quality transmission solutions that meet international standards and improve the transmission accuracy and efficiency of equipment in various industries.

Compared with traditional rubber synchronous belts, polyurethane synchronous belts have many unique advantages in improving the performance of industrial equipment. Polyurethane synchronous belts are made of thermoplastic polyurethane (PU) material, which has extremely high wear resistance, oil resistance, chemical corrosion resistance and excellent dimensional stability. These characteristics enable them to work stably and long-term under high load, high speed and harsh environment. When combined with precision-made synchronous pulleys, polyurethane synchronous belts can ensure precise synchronous motion and avoid the slip problem that may occur in traditional belt drives, thereby improving transmission efficiency and system accuracy.

The wear resistance and aging resistance of polyurethane synchronous belts make them last longer than traditional rubber belts under heavy load conditions. In industrial equipment such as CNC machine tools, precision instruments and automated production lines, the requirements for high-precision transmission are particularly stringent. Due to its high strength, polyurethane synchronous belts can effectively reduce wear and extend service life, thereby reducing equipment failure rate and maintenance costs, which not only improves the stability of the production line, but also improves the overall performance of the equipment.

The oil resistance and chemical corrosion resistance of polyurethane synchronous belts make them particularly suitable for industrial applications involving oils, chemicals and high temperature environments. In many industrial environments, transmission belts need to come into contact with lubricants, cutting fluids or chemicals. Traditional rubber belts often cannot withstand these harsh working conditions. However, polyurethane synchronous belts can continue to perform well in these harsh environments due to their excellent oil resistance, solvent resistance and chemical corrosion resistance, thereby reducing downtime and maintenance frequency.

Polyurethane synchronous belts also have lower elastic deformation and better heat resistance, ensuring that they can still maintain efficient transmission performance in high temperature and high load working environments. Many high-precision equipment, such as CNC machine tools and industrial robots, generate a lot of heat during operation, requiring transmission belts with good heat resistance and stability. The stability of polyurethane synchronous belts enables them to ensure efficient operation of equipment, which is very suitable for high-performance working environments with strict requirements for high temperature resistance.

Ningbo Slongwang Synchronous Belt Co,.Ltd. uses advanced manufacturing processes to produce polyurethane synchronous belts, ensuring the uniformity and dimensional accuracy of the belt. This allows more precise meshing between the belt teeth and the synchronous pulleys, which not only improves the transmission efficiency of the equipment, but also reduces noise and vibration, improving the comfort and safety of the working environment. In industrial environments that have high requirements for quiet operation or noise-sensitive workplaces, polyurethane synchronous belts are undoubtedly an ideal choice.

In modern industry, the automation and precision of production lines are key factors in improving production efficiency and product quality. With its high-precision transmission performance, polyurethane synchronous belts ensure the synchronous operation of equipment and avoid errors and deviations in mechanical transmission. This is essential for automated production lines involving processes such as precision machining, packaging and conveying.

English

English 中文简体

中文简体