-

Features of multi-V belts:

1. The transmission power is large, and the transmission power is 30% higher than that of ordinary V-belts in the same space.

2. The belt body is thin and flexible, which is suitable for transmission with small pulley diameter and high-speed transmission. The belt speed can reach 40m/s:

3. The addition of short fiber reinforcement can withstand higher lateral pressure, increase the belt wedge pressure performance, and reduce deformation after force; and the structure is compact, the vibration is small, and the operation is more stable.

4. It has the characteristics of cold and heat resistance, oil resistance, corrosion resistance, bending resistance, wear resistance, aging resistance, small elongation in use, and long service life.

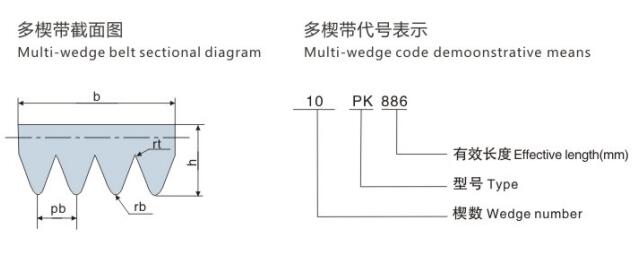

Multi-V belt cross-section size

Model PH PJ PK PL PM Wedge distance 1.60 2.34 3.56 4.70 9.40 Wedge top arc radius rb, minimum value 0.30 0.40 0.50 0.40 0.75 Groove bottom arc radius rt, maximum value 0.15 0.20 0.25 0.40 0.75 With height h, approximate 2.6±0.1 3.6±0.2 4.8±0.3 7.0±0.3 12±0.3 PH type

Specification Effective length PH509

PH561

PH621

PH701

PH725509.00

561.00

621.00

701.00

725.00PH770

PH848

PH412

PH977

PH1044770.00

848.00

412.00

977.00

1044.00PH1131

PH1169

PH1217

PH1278

PH13821131.00

1169.00

1217.00

1278.00

1382.00PH1476

PH1517

PH1646

PH1725

PH18321476.00

1517.00

1646.00

1725.00

1832.00PH1942

PH2141

PH26661942.00

2141.00

2666.00PJ Type

Specification Effective length PJ508

PJ560

PJ620

PJ700

PJ724508.00

560.00

620.00

700.00

724.00PJ769

PJ847

PJ411

PJ976

PJ1043769.00

847.00

411.00

976.00

1043.00PJ1130

PJ1168

PJ1216

PJ1277

PJ13811130.00

1168.00

1216.00

1277.00

1381.00PJ1475

PJ1516

PJ1645

PJ1724

PJ18311475.00

1516.00

1645.00

1724.00

1831.00PJ1941

PJ2195

PJ26651941.00

2195.00

2665.00PK type

Specification Effective length PK503

PK555

PK615

PK695

PK719503.00

555.00

615.00

695.00

719.00PK764

PK842

PK956

PK971

PK1038764.00

842.00

956.00

971.00

1038.00PK1125

PK1163

PK1211

PK1272

PK13761125.00

1163.00

1211.00

1272.00

1376.00PK1470

PK1511

PK1640

PK1719

PK18261470.00

1511.00

1640.00

1719.00

1826.00PK1936

PK2190

PK26601936.00

2190.00

2660.00PL Type

Specification Effective length PL683

PL707

PL752

PL830

PL944683.00

707.00

752.00

830.00

944.00PL959

PL1026

PL1113

PL1151

PL1199959.00

1026.00

1113.00

1151.00

1199.00PL1260

PL1364

PL1458

PL1499

PL16281260.00

1364.00

1458.00

1499.00

1628.00PL1707

PL1814

PL1924

PL2178

PL22501707.00

1814.00

1924.00

2178.00

2250.00PL2362

PL2482

PL27512362.00

2482.00

2751.00PM Type

Specification Effective length PM1322

PM1335

PM1364

PM1375

PM14451322.00

1335.00

1364.00

1375.00

1445.00PM1470

PM1492

PM1524

PM1550

PM16151470.00

1492.00

1524.00

1550.00

1615.00PM1642

PM1678

PM1766

PM1810

PM20151642.00

1678.00

1766.00

1810.00

2015.00PM2155

PM2220

PM2295

PM2330

PM24532155.00

2220.00

2295.00

2330.00

2453.00PM2772

PM2900

PM31002772.00

2900.00

3100.00 -

Multi Wedge Belt

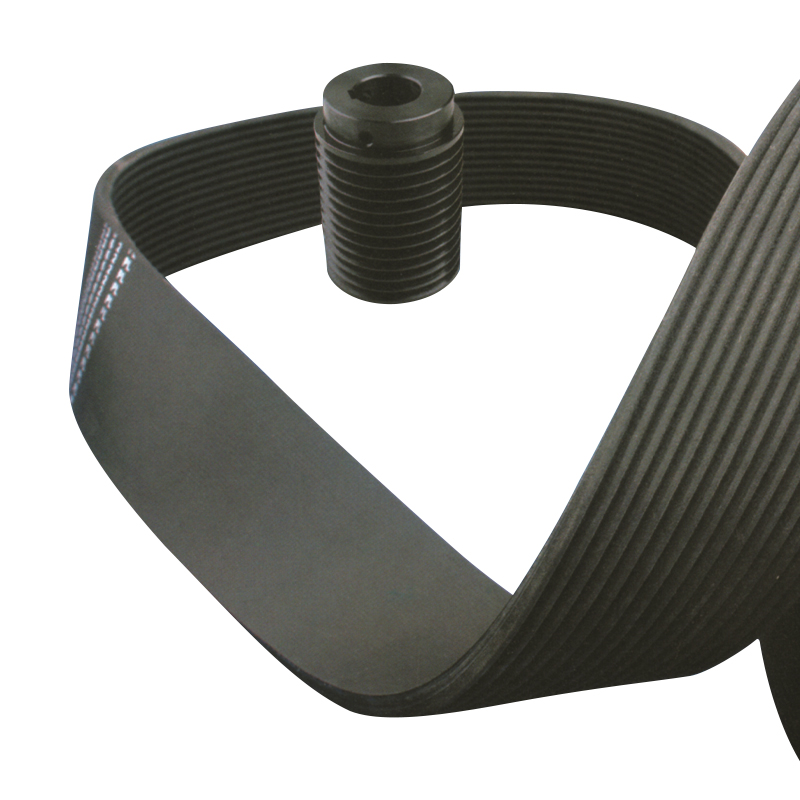

Multi-V belt, also known as multi-groove belt or multi-slot belt, is a kind of annular rubber transmission belt with flat belt as base and 40° trapezoidal wedges arranged on the inner surface at equal intervals. Its working surface is the side of the wedge. The structural characteristics of multi-V belt make it have the advantages of large transmission power, small vibration and smooth operation during transmission. It is particularly suitable for transmission occasions requiring more V-belts or the wheel axis is perpendicular to the ground.

1. The transmission power is large, and the transmission power is 30% higher than that of ordinary V-belts in the same space.

2. The belt body is thin and flexible, which is suitable for transmission with small pulley diameter and high-speed transmission. The belt speed can reach 40m/s:

3. The addition of short fiber reinforcement can withstand higher lateral pressure, increase the belt wedge pressure performance, and reduce deformation after force; and the structure is compact, the vibration is small, and the operation is smoother.

4. It has the characteristics of cold and heat resistance, oil resistance, corrosion resistance, bending resistance, wear resistance, aging resistance, small elongation in use, and long service life.

Contact Us

Contact Us

Return To The Previous Page

Return To The Previous Page

Located by the affluent and beautiful Hangzhou Bay, our company enjoys a scenic location with mountains and water, and a talented workforce. The old factory is situated along the 329 National Road in Longshan Town, while the new factory is conveniently located in the Longshan Industrial Park by the sea. In the past twenty years, through the hard work and innovation of our dedicated employees, we have established strong cooperative relationships with nearly a thousand clients in China and are expanding into international markets. Our company is equipped with advanced machinery, standardized manufacturing processes, comprehensive testing equipment, and strict enterprise management. Our technical management team, which includes some of the earliest developers of synchronous belt transmission products in China, boasts a wealth of professional experience. We have obtained ISO 9001:2000 certification, ensuring the quality of our products, which are widely used and recognized by clients in various industries both domestically and internationally, earning a good reputation for the "Slongwang" brand.

Our products are extensively used in various industries, including machine tools, textiles, printing, food packaging, home appliances, engraving, wire and cable, instruments, petrochemicals, tobacco, and communications, for the transmission of new mechanical drives.

Adhering to the traditional virtues of "sincerity, honesty, and earnestness," Slongwang advocates for high-quality and affordable products to achieve a win-win situation. We strive to lead the market with reliable products, more favorable prices, and faster delivery times, aiming to attract a broader range of partners. With a vision to establish a strong and large enterprise that stands the test of time, we are committed to creating a century-old business. We are eager to work with visionaries worldwide to forge a brilliant future.

Synchronous pulley consists of a circular belt with evenly spaced teeth on its inner circumference and a correspondingly engaging pulley. It combines the advantages of belt drives, chain drives, and gear drives. During transmission, power is transferred through the meshing of the belt teeth with the pulley's tooth grooves.

Synchronous pulley offers precise transmission ratios, no slippage, and constant speed ratios, ensuring smooth operation, vibration absorption, low noise, a wide range of transmission ratios (up to 1:10), and allowable linear speeds of up to 50 m/s. It can transmit power from a few watts to hundreds of kilowatts. With high transmission efficiency, generally reaching 98%, it is compact, suitable for multi-shaft transmission, and requires no lubrication, making it pollution-free and ideal for environments where contamination is not allowed or where working conditions are harsh.

-

Jan 28,2026In modern industrial operations, efficiency, reliability, and cost-effectiveness are paramount. Industrial equipment suc...Read More

-

Jan 21,2026In the world of construction and heavy machinery, efficiency, durability, and reliability are paramount. From excavators...Read More

-

Jan 14,2026In today’s fast-paced industrial environment, the demand for higher efficiency, reliability, and precision in manufactur...Read More

-

Jan 07,2026In the world of mechanical systems, reliability is a key factor that determines the efficiency, longevity, and performan...Read More

Efficient and stable multi-V belts: the key to improving equipment performance

Ningbo Slongwang Synchronous Belt Co,.Ltd. is a leading synchronous belt and drive belt manufacturer in China, focusing on providing high-quality belt drive solutions. The company not only produces synchronous belts and pulleys that meet international standard tooth shapes, but also covers a variety of belt drive products such as multi-V belts (also known as multi-groove belts or multi-slot belts), V-belts, flat belts, etc. As one of its products, multi-V belts are widely used in many industrial applications due to their excellent transmission characteristics.

The structural design of multi-V belts gives them unique advantages in transmission efficiency and stability. Compared with traditional V-belts, multi-V belts can transmit more power in the same space, especially for transmission systems that require multiple V-belts or axles perpendicular to the ground. Its inner surface is composed of multiple 40° trapezoidal wedges arranged at equal intervals. This structure enables the multi-V belt to maintain low vibration during high load and high-speed operation, and the transmission is smooth and the operation noise is low.

The transmission power of multi-V belts is large. Due to its compact structure and special trapezoidal wedge design, multi-V belts can transmit about 30% more power than ordinary V belts in the same space. This enables the multi-V belt to bear a larger load in a limited space, improving the working efficiency of the equipment. In some occasions where high power transmission is required, such as large mechanical equipment, high-speed production lines, and machinery requiring high-precision transmission, the multi-V belt provides a more efficient solution.

The multi-V belt has a thinner and more flexible belt body design, which is suitable for pulleys with small diameters and high-speed transmission systems. This design allows the multi-V belt to remain stable at high speeds, and the belt speed can reach 40m/s. The high belt speed makes it perform well in industrial applications that require fast transmission and high efficiency, such as automated production lines, food processing, and precision instruments.

In the design of the multi-V belt, short fiber reinforcement materials are used, which greatly improves the strength and durability of the belt body. By adding reinforcement materials, the multi-V belt can withstand higher side pressure, improve the wedge pressure performance of the belt, and reduce the deformation of the belt body caused by excessive pressure. This feature enables the multi-V belt to work stably under high load conditions, further improving its service life and reliability.

The multi-V belt also has good environmental resistance. It has the advantages of cold and heat resistance, oil resistance, corrosion resistance, bending resistance, wear resistance, and aging resistance, which enable it to adapt to various harsh working environments. Whether under low or high temperature conditions, or in an environment exposed to oils and chemicals, the multi-V belt can maintain stable transmission performance, reducing equipment failures and maintenance costs caused by environmental factors.

The multi-V belt has a small elongation in use and can maintain stable transmission performance for a long time, which makes it have a long service life in long-term use. Compared with traditional transmission belts, the multi-V belt can effectively reduce the replacement frequency and maintenance costs due to its wear resistance and durability, thereby reducing the overall operating costs.

Ningbo Slongwang Synchronous Belt Co,.Ltd. As a professional manufacturer of multi-V belts, it adopts advanced production technology to ensure that each multi-V belt meets strict quality standards. The company ensures the excellent performance of multi-V belts under high load, high speed and complex working conditions through continuous innovation and optimization of production processes. With many years of industry experience, Ningbo Slongwang Synchronous Belt Co., Ltd.'s multi-V belts have been widely recognized in domestic and foreign markets and are used in many fields, including automation equipment, food packaging, electronic equipment, automotive industry, and precision machinery.

Advantages of multi-V belts: high power transmission and environmental resistance

As a specially designed transmission belt, multi-V belts are widely used in many industrial fields for their good transmission performance and environmental resistance. Ningbo Slongwang Synchronous Belt Co,.Ltd., as one of China's leading manufacturers of synchronous belts and related belt transmission products, produces multi-V belts with excellent power transmission capacity, low vibration running characteristics and good environmental adaptability, especially suitable for high-load, compact space and high-speed transmission systems.

The design structure of multi-V belts enables them to transmit higher power than traditional V-belts in a limited space. Compared with traditional V-belts, multi-V belts use multiple equally spaced trapezoidal wedges. This design effectively increases the contact area of the working surface and allows more power to be transmitted in the same space. The power transmission capacity of multi-V belts produced by Ningbo Slongwang is generally 30% higher than that of ordinary V-belts in the same space. This makes them very suitable for industrial applications that require high power density, especially in some transmission systems with limited space but large loads.

The thin and flexible belt body design of multi-V belts enables them to adapt to smaller pulley diameters and work stably under high-speed transmission conditions. The belt speed can reach 40m/s, which provides reliable guarantee for equipment that needs high-speed and efficient operation.

The structural characteristics of the multi-V belt enable it to reduce vibration during operation and improve the stability of the transmission system. Traditional V-belt transmission often causes equipment instability due to vibration during operation, and even affects the long-term service life of the equipment. The wedge structure of the multi-V belt allows each wedge to be evenly stressed during the transmission process, reducing the vibration and offset of a single belt tooth, thereby greatly reducing the overall vibration. This makes the multi-V belt particularly outstanding in high-load and high-power transmission systems, ensuring smooth and reliable operation of the equipment.

Another feature of the multi-V belt is its environmental resistance. Ningbo Slongwang's multi-V belts are made of high-quality rubber and reinforcement materials, which can withstand extreme environmental conditions, including high temperature, low temperature, oil pollution, corrosion, etc. They have excellent characteristics such as resistance to cold and heat, oil resistance, corrosion resistance, wear resistance, and aging resistance. This enables the multi-V belt to operate reliably in various harsh industrial environments, especially in chemical, metallurgical, mining and other fields with strict requirements on equipment.

The temperature resistance of the multi-V belt also makes it perform well in high temperature environments. In many high-temperature production situations, traditional transmission belts may deform and fail due to excessive temperatures. The high temperature resistance of multi-V belts ensures that they can maintain stable performance in high temperature environments for a long time.

Poly-V belts adopt a compact design, with thin and flexible belt bodies, so they are suitable for pulleys with smaller diameters and can achieve efficient transmission in a small space. For many industrial equipment, especially where multiple transmission belts need to be shared in a limited space, multi-V belts provide an ideal solution. By effectively utilizing limited space, multi-V belts can not only improve transmission efficiency, but also reduce the size of the equipment, making the overall equipment design more compact.

The multi-V belts produced by Ningbo Slongwang Synchronous Belt Co,.Ltd. are widely used in various industrial equipment due to their excellent transmission efficiency and environmental resistance. They are especially suitable for industrial automation equipment, robots, packaging machinery, mining equipment, etc. Whether it is a high-speed transmission system or a high-load condition, multi-V belts can provide stable and reliable performance.

In applications with high precision requirements such as industrial robots and CNC machine tools, multi-V belts can ensure the efficient operation of equipment with their precise transmission performance. In situations where long-term, high-load operation is required, it can especially reduce the number of maintenance times and extend the service life of equipment.

English

English 中文简体

中文简体