Textile Industry

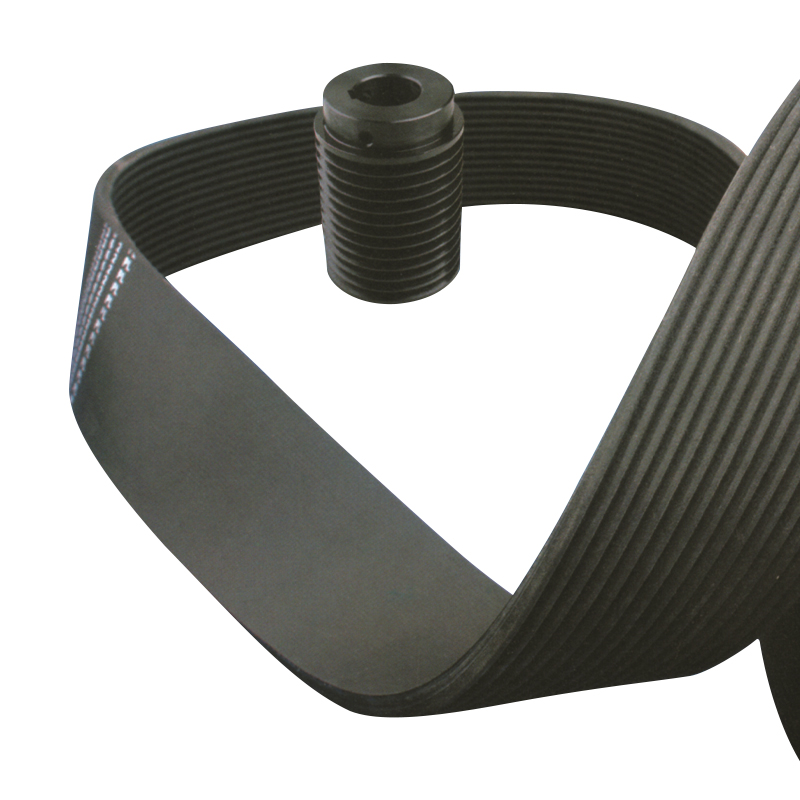

In the textile industry, synchronous belt plays an important role, mainly used for transmission and control. Here are some solutions and applications for synchronous belts in the textile industry:

Transmission system

Stability: The synchronous belt provides stable transmission, ensuring the accuracy and reliability of the equipment during high-speed operation.

Low Noise: The noise level of the synchronization belt is lower compared to traditional transmissions, thus contributing to a better working environment.

Equipment Application

Braiding machine: used to control the speed and accuracy of the braiding machine to ensure the quality of the fabric during the production process.

Dye Machine: In dyeing and finishing equipment, the synchronization belt ensures dyeing and processing.

Energy efficiency

Reduced Energy Loss: The synchronous belt is designed to enable more efficient energy transmission, reduce overall energy consumption and help companies save costs.

Convenient maintenance

Easy to replace: The maintenance and replacement of synchronous belts are relatively simple, reducing equipment downtime and improving production efficiency.

Customized solutions

To meet different needs: Provide customized synchronization belt solutions according to the requirements of different equipment to meet specific operating conditions and environments.

Industry Standards

Comply with industry standards: Use synchronous belt products that comply with international standards to ensure product quality and safety.

in conclusion

By adopting synchronous belt solutions in the textile industry, companies can improve equipment performance, reduce energy consumption and increase production efficiency. With proper design and application, companies can maintain a competitive advantage in challenging markets.

Related Product

-

Tel: +86-400-670-3800

-

Tel: +86-574-58967770

-

Phone: +86-18867628822

-

FAX: +86-574-63990099

-

Email: llm@cn-slw.com

English

English 中文简体

中文简体