Rubber timing belt vs. polyurethane timing belt: performance differences and application prospects

2025-09-17

Content

- 1 Introduction

- 2 What is a Rubber Timing Belt?

- 3 What is a Polyurethane Timing Belt?

- 4 Key Differences: Rubber vs. Polyurethane Timing Belts

- 5 Applications of Rubber Timing Belts

- 6 Applications of Polyurethane Timing Belts

- 7 Advantages and Disadvantages

- 8 Factors to Consider When Choosing

- 9 Maintenance and Care

- 10 Future Trends and Innovations

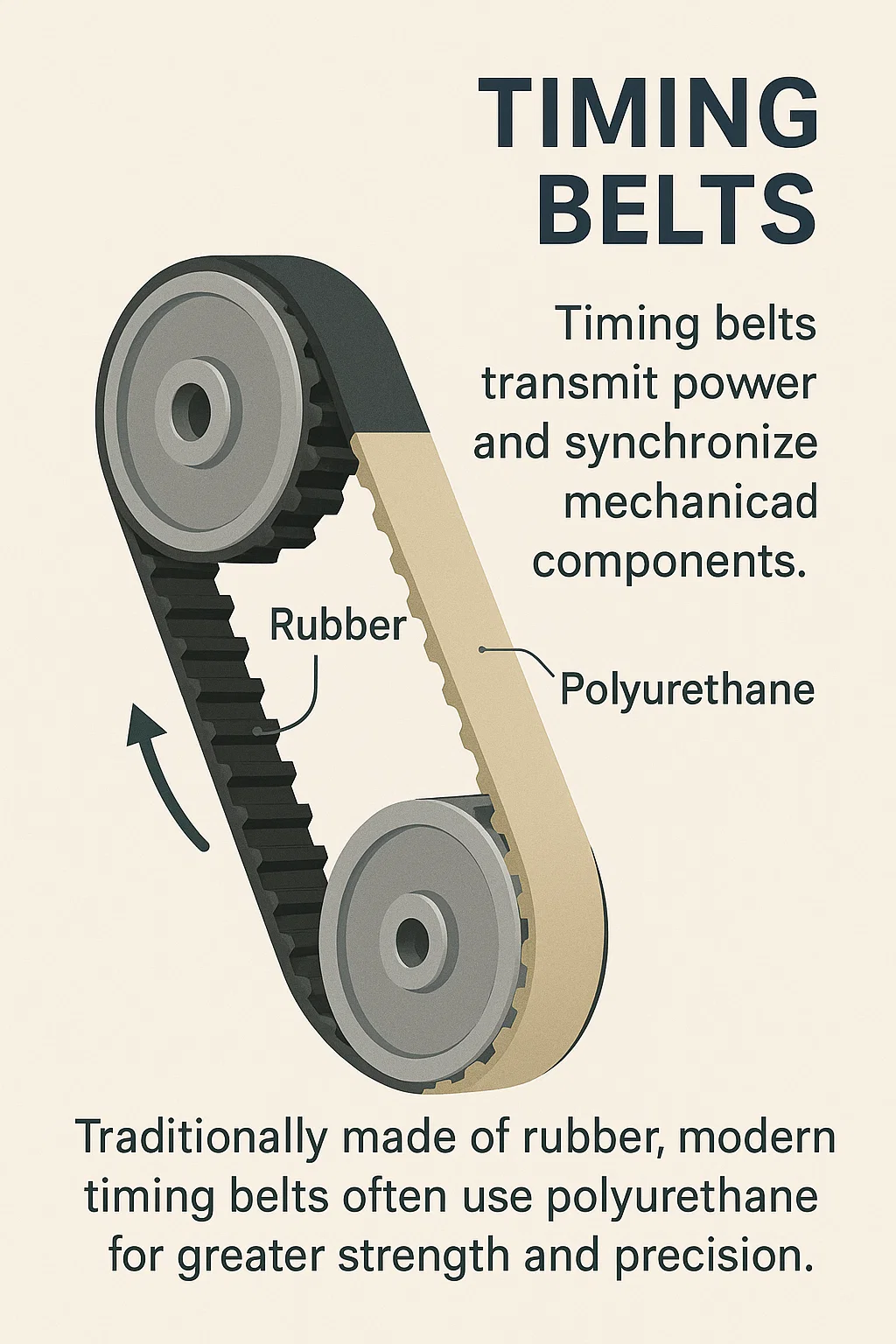

Introduction

Timing belts are critical components in a wide range of mechanical systems, from the engines of our cars to the sophisticated robotics on a factory floor.Their primary function is to transmit power and synchronize the rotation of two or more shafts, ensuring that mechanical parts move in perfect harmony. This precision is essential for the efficient and reliable operation of machinery. While the fundamental purpose of timing belts remains constant, the materials used to manufacture them have evolved to meet the diverse and demanding requirements of modern applications.Historically, rubber has been the go-to material for timing belts due to its excellent flexibility and cost-effectiveness. However, the rise of automation, robotics, and high-precision machinery has led to the increased use of polyurethane, a synthetic polymer known for its superior strength and precision.

What is a Rubber Timing Belt?

A rubber timing belt is a flexible, toothed belt used for power transmission and synchronization in various mechanical systems. It is the traditional and most widely used type of timing belt, prized for its durability, flexibility, and cost-effectiveness. The fundamental design consists of a continuous loop with teeth molded onto its inner surface, which mesh with corresponding grooves on pulleys to ensure synchronized movement without slippage.

Composition and Materials

While referred to as "rubber," these belts are sophisticated composite products. The main body is made from synthetic rubber compounds, with the two most common types being Neoprene (Polychloroprene) and HNBR (Hydrogenated Nitrile Butadiene Rubber).

-

Neoprene (CR): Neoprene is a versatile synthetic rubber known for its good balance of properties. It offers decent resistance to oils, weather, and ozone, making it suitable for a wide range of general-purpose applications. It is often the material of choice for timing belts in printers, copiers, and many industrial machines.

-

HNBR (Hydrogenated Nitrile Butadiene Rubber): HNBR is a more advanced synthetic rubber that is a result of hydrogenating nitrile rubber. This process enhances its properties, providing superior resistance to heat, oil, and chemicals. HNBR belts are commonly found in automotive engines, where they must withstand extreme temperatures and exposure to engine fluids.

Beyond the rubber compound, a timing belt's strength and dimensional stability are provided by internal reinforcement. High-strength cords, typically made of fiberglass or aramid (Kevlar), are embedded within the belt's structure. These cords, known as the "tension member," are crucial as they prevent the belt from stretching under load, ensuring accurate timing and maintaining the correct pitch between teeth. The teeth and backing of the belt are often covered with a protective layer of nylon fabric to improve wear resistance, reduce friction, and lower noise levels.

Manufacturing Process

The production of rubber timing belts is a multi-step process that combines molding and curing. The process generally involves:

-

Compound Mixing: The synthetic rubber base is mixed with various additives, such as carbon black and plasticizers, to achieve the desired physical properties like hardness and flexibility.

-

Cord Placement: The reinforcement cords are precisely wound into a circular mold to form the tension member.

-

Molding and Vulcanization: The rubber compound is then applied to the mold, enveloping the cords and forming the teeth and backing. The assembly is then subjected to heat and pressure in a process called vulcanization. This cures the rubber, cross-linking the polymer chains to give the belt its final, durable form.

-

Finishing: After cooling, the belt is removed from the mold, and any excess material is trimmed. The final product is a seamless, endless belt ready for use.

What is a Polyurethane Timing Belt?

A polyurethane timing belt is a modern alternative to the traditional rubber belt, engineered for applications that demand high precision, cleanliness, and superior durability. Unlike rubber, which is a thermoset material, polyurethane (PU) is a thermoplastic elastomer, which allows for different manufacturing processes and provides distinct performance advantages. These belts are characterized by their smooth, often white or clear appearance and are particularly favored in industries where hygiene and accuracy are paramount.

Composition and Materials

The core of a polyurethane timing belt is its body, which is made from a polyurethane compound. There are two primary types of polyurethane used:

-

Ester-based polyurethane: This type offers excellent tensile strength, abrasion resistance, and a high load capacity. However, it can be susceptible to hydrolysis, which is degradation in the presence of water or high humidity over time.

-

Ether-based polyurethane: Known for its superior resistance to hydrolysis, ether-based polyurethane is more stable in moist environments. It also maintains good flexibility at low temperatures, making it suitable for a wider range of operating conditions, although its tensile strength may be slightly lower than that of ester-based PU.

Similar to rubber belts, the tensile strength of a polyurethane belt comes from internal reinforcement. The most common tension members are steel cords, which provide exceptional dimensional stability and very low elongation, ensuring precise and consistent timing. For applications requiring more flexibility or a non-magnetic material, Kevlar (aramid) or stainless steel cords are also used. A nylon or other fabric facing may be added to the teeth to reduce the coefficient of friction, improve wear resistance, and decrease noise.

Manufacturing Process

The manufacturing of polyurethane timing belts is distinct from the vulcanization process used for rubber. The two main methods are extrusion and molding.

-

Extrusion: This process is used to create open-ended timing belts. Molten polyurethane is pushed through a die, which forms the continuous profile of the belt, including its teeth and body. The reinforcing cords are fed into the extruder at the same time, becoming an integral part of the belt's structure. These belts are then cut to the desired length and can be joined to form an endless belt using a thermal welding process.

-

Molding: For truly endless, high-precision belts, a casting or molding process is used. A mold is filled with liquid polyurethane, which encapsulates the precisely placed tension cords. This method allows for a seamless belt without any splices or joints, providing maximum strength and dimensional stability, making it ideal for high-load and critical synchronization applications.

Key Differences: Rubber vs. Polyurethane Timing Belts

The choice between a rubber and a polyurethane timing belt hinges on a detailed understanding of their material properties and performance characteristics. While they both serve the same fundamental purpose, their differing compositions result in distinct advantages and disadvantages across various applications.

Material Properties

|

PropertyRubber |

Timing BeltsPolyurethane |

Timing Belts |

|

Composition |

Neoprene or HNBR synthetic rubber with fiberglass or aramid cords. |

Ester-based or ether-based polyurethane with steel or Kevlar cords. |

|

Tensile Strength |

Good. Suitable for many general-purpose power transmission applications. |

Excellent.Significantly higher strength due to the inherent properties of polyurethane and common steel cord reinforcement. |

|

Elongation |

Higher elongation under load, which can lead to stretch over time and reduced timing accuracy. |

Very low elongation, especially with steel cords. Maintains dimensional stability and high precision. |

|

Hardness |

Typically softer, with a lower Shore A hardness rating (e.g., 80 Shore A). This contributes to good flexibility and vibration dampening. |

Generally harder, with a higher Shore A hardness rating (e.g., 90 Shore A). This provides greater rigidity and precision but less flexibility. |

|

Temperature Resistance |

Good. HNBR rubber offers a wide temperature range, typically from -30°C to +130°C, making it suitable for automotive engines. |

Good, but often with a narrower range for continuous use, typically from -30°C to +80°C. Some specialized formulations can extend this range. |

|

Chemical Resistance |

Varies by rubber type. Neoprene has fair resistance to oil, but HNBR offers superior resistance to a wider range of chemicals and oils. |

Excellent. Polyurethane is highly resistant to oils, greases, fats, and many chemicals, which is crucial for food processing and industrial applications. |

|

Abrasion Resistance |

Good. The natural flexibility and composition of rubber allow it to handle particulate matter and rough surfaces effectively. |

Excellent. Polyurethane's inherent toughness provides superior resistance to wear, cuts, and abrasion, resulting in a longer lifespan in high-wear environments. |

Performance Characteristics

-

Load Capacity: Polyurethane belts generally have a higher load capacity due to their superior tensile strength and low elongation. The steel tension members allow them to transmit more power and handle heavier loads without stretching or deforming.

-

Precision and Accuracy: This is a key differentiator. The minimal elongation of polyurethane belts ensures exceptional precision, making them the preferred choice for applications where exact positioning and synchronized movement are critical, such as in robotics and CNC machinery. Rubber belts, with their greater stretch, are less suitable for these high-precision tasks.

-

Noise Levels: Rubber's softer, more elastic composition and vibration dampening properties typically result in a quieter operation. Polyurethane belts, being harder and more rigid, can sometimes generate more noise, especially at high speeds or under high tension.

-

Vibration Dampening: Rubber excels at dampening vibrations and absorbing shocks, which is a significant advantage in applications where smooth operation and noise reduction are important, such as in automotive engines or printers. Polyurethane belts are less effective at dampening vibrations due to their rigidity.

Durability and Lifespan

-

Wear Resistance: Polyurethane belts offer excellent wear resistance, particularly against abrasion and tooth shear. This makes them last longer in dirty or high-friction environments. While rubber belts are also durable, they are more prone to wear and shedding in abrasive conditions.

-

Aging Effects: Rubber, especially Neoprene, is susceptible to degradation from ozone and UV exposure over time, leading to cracking and hardening. This process, known as "aging," can shorten the belt's lifespan. Polyurethane is more resistant to these environmental factors, providing a longer and more stable service life.

-

Environmental Factors: The higher chemical resistance of polyurethane makes it a more reliable option in environments exposed to oils, solvents, or cleaning agents. The superior temperature range of HNBR rubber, on the other hand, makes it better suited for the high-heat conditions of an engine bay.

Applications of Rubber Timing Belts

Rubber timing belts, with their balance of flexibility, durability, and cost-effectiveness, are the workhorses of power transmission in a wide variety of industries. Their resilience and ability to absorb shock make them a reliable choice for many common applications.

Automotive Industry

This is arguably the most well-known and critical application for rubber timing belts.

-

Engine Timing: In many internal combustion engines, a rubber timing belt is used to synchronize the rotation of the crankshaft and the camshaft. This ensures that the engine's valves open and close at the precise moments required for the four-stroke cycle, guaranteeing efficient combustion. The HNBR rubber used in these belts is specifically formulated to withstand the high temperatures, oil, and continuous stress found within an engine bay.

-

Accessory Drives: While serpentine belts are more common for accessories, some older designs and specific applications still use smaller timing belts to drive components like water pumps, oil pumps, or superchargers.

Industrial Machinery

Rubber timing belts are a staple in general-purpose industrial equipment where robust power transmission is needed without the need for extremely high precision.

-

Conveyor Systems: In material handling, rubber timing belts are widely used for conveying products. Their flexibility allows them to wrap around pulleys with smaller diameters, and their toothed design ensures that the conveyor moves at a constant, non-slip speed, which is crucial for manufacturing lines.

-

Power Transmission: Many types of industrial machinery, from mixers and presses to looms and woodworking tools, use rubber timing belts for power transmission. They are a reliable and lower-maintenance alternative to traditional chains and gears.

Other Applications

The versatility of rubber timing belts extends to a variety of other consumer and commercial devices.

-

Printers and Copiers: In office equipment, timing belts are essential for moving the print heads and paper trays with synchronized motion. The lower noise and vibration dampening properties of rubber are a significant advantage in these applications, as they contribute to quieter operation.

-

Household Appliances: From vacuum cleaners to washing machines, timing belts are used to transmit power from the motor to various mechanical components.

-

Fitness Equipment: Treadmills and other exercise machines use timing belts to drive their moving parts, providing a reliable and smooth user experience.

Applications of Polyurethane Timing Belts

Polyurethane timing belts, with their superior strength, dimensional stability, and resistance to environmental factors, are the preferred choice for high-tech, precision-driven, and specialized applications where performance and reliability are non-negotiable.

Robotics

The demand for pinpoint accuracy and repeatable motion makes polyurethane belts indispensable in robotics.

-

Precision Movement: In robotic arms and linear actuators, these belts are used to control the movement of joints and end effectors. The minimal elongation of steel-reinforced polyurethane belts ensures that the robot can move to the exact coordinates specified by its programming, a critical requirement for tasks like welding, assembly, and pick-and-place operations.

Automation and Material Handling

Polyurethane belts are a cornerstone of modern automation due to their durability and cleanliness.

-

High-Precision Equipment: Industries like electronics manufacturing rely on timing belts for the precise positioning of components on circuit boards. Automated inspection systems and sorting machines also utilize these belts to ensure components are moved and aligned with sub-millimeter accuracy.

-

Material Handling: In material handling systems, especially those dealing with heavy loads or requiring high speeds, polyurethane belts provide the necessary strength and wear resistance. They are commonly used in automated warehouses and distribution centers for conveyors that move large or heavy items.

High-Precision Equipment

The low-stretch and high-strength characteristics of polyurethane make it the ideal material for sensitive and critical applications.

-

Medical Devices: In medical equipment such as diagnostic machinery, lab automation, and patient handling systems, timing belts must operate with extreme precision and reliability. Polyurethane's non-shedding nature and resistance to chemicals and cleaning agents are also crucial for maintaining a sterile environment.

-

Scientific Instruments: From telescopes to microscopes and spectrometers, scientific instruments require belts that provide precise, repeatable motion to adjust and position delicate components. The dimensional stability of polyurethane belts ensures that the instrument's calibration and accuracy are maintained over time.

Clean Room and Food Processing

Polyurethane belts are a top choice for sterile environments.

-

Clean Room Applications: The non-shedding property of polyurethane makes it suitable for clean room environments, such as those used in semiconductor manufacturing and pharmaceuticals, where airborne particulates must be kept to an absolute minimum.

-

Food Processing: The excellent chemical and abrasion resistance of polyurethane means it can withstand repeated wash-downs with harsh cleaning agents and exposure to food products without degrading. Belts with a smooth or fabric-coated surface are used for conveying food items, meeting stringent hygiene standards.

Advantages and Disadvantages

Choosing between a rubber and a polyurethane timing belt is a matter of weighing their respective strengths and weaknesses against the specific needs of the application. Both materials offer distinct benefits and trade-offs in terms of cost, performance, and durability.

Rubber Timing Belts

Advantages

-

Cost-Effective: Rubber timing belts are generally less expensive to manufacture than their polyurethane counterparts, making them a cost-effective solution for a wide range of general-purpose applications. This lower initial cost is a major factor in their widespread use.

-

Good Flexibility: The softer composition of rubber allows for greater flexibility. This means they can be used with smaller diameter pulleys and in applications that require belts to navigate tight turns or complex paths.

-

Excellent Vibration Dampening: Rubber's natural elasticity makes it highly effective at absorbing shocks and dampening vibrations. This leads to quieter operation and reduces wear on bearings and other components, making it ideal for systems where noise reduction is a priority.

-

Proven Technology: Rubber timing belts have been used for decades and are a well-understood and reliable technology. Their performance is predictable, and there is a vast amount of data and expertise available regarding their use and maintenance.

Disadvantages

-

Lower Strength: Compared to polyurethane, rubber has a lower inherent tensile strength and is more susceptible to stretching under heavy loads. This can lead to reduced timing accuracy and a shorter lifespan in high-stress applications.

-

Less Chemical Resistance: While HNBR offers good resistance to oils, rubber in general is more vulnerable to degradation from exposure to certain chemicals, solvents, and ozone, which can lead to premature failure.

-

Aging Effects: Rubber can become brittle and crack over time due to exposure to UV light and environmental factors, a process known as "aging." This necessitates regular inspection and replacement.

-

Potential for Shedding: In high-wear applications, rubber belts can shed small particles, which can be an issue in clean room environments or food processing plants.

Polyurethane Timing Belts

Advantages

-

High Strength and Load Capacity: Reinforced with steel or aramid cords, polyurethane belts offer exceptional tensile strength and very low elongation. This allows them to handle significantly higher loads and provide superior power transmission compared to rubber.

-

Excellent Chemical Resistance: Polyurethane is highly resistant to oils, greases, solvents, and other chemicals, making it ideal for use in industrial settings where such substances are present.

-

Superior Precision and Accuracy: The low stretch of polyurethane belts ensures that they maintain their dimensional stability, providing extremely accurate and repeatable positioning. This is a critical advantage for robotics and other high-precision machinery.

-

Abrasion and Wear Resistance: Polyurethane is inherently tough and durable, providing excellent resistance to abrasion and tooth wear. This translates to a longer service life in harsh environments.

-

Clean Operation: Polyurethane belts do not shed particles like rubber can, making them the material of choice for clean room and food-grade applications where contamination is a concern.

Disadvantages

-

Higher Cost: The specialized materials and manufacturing processes for polyurethane belts make them more expensive than rubber belts, both in initial purchase and replacement.

-

Less Flexible: The higher hardness and rigidity of polyurethane make these belts less flexible than rubber ones. This can be a disadvantage in applications with small pulley diameters or complex routing paths.

-

Potential for More Noise: Due to their rigidity, polyurethane belts can be louder in operation, particularly at high speeds, and they are less effective at dampening vibrations.

-

Susceptibility to Hydrolysis (Ester-based): Ester-based polyurethane can degrade over time when exposed to water or high humidity, which can be a limiting factor in some applications. However, ether-based polyurethane largely mitigates this issue.

Factors to Consider When Choosing

Selecting the right timing belt is a critical decision that directly impacts the performance, longevity, and cost-effectiveness of a mechanical system. A thorough evaluation of the application's specific requirements is essential. Here are the key factors to consider when deciding between a rubber and a polyurethane timing belt.

Application Requirements

The first and most important consideration is the nature of the application itself.

-

Load and Speed: For high-torque and heavy-load applications, the superior tensile strength and low elongation of polyurethane belts make them the clear choice. Their ability to handle greater forces without stretching ensures a reliable power transfer. For lighter loads or applications with moderate speed requirements, rubber belts are often sufficient and more economical.

-

Precision and Accuracy: If the application requires precise and repeatable positioning, such as in robotics, CNC machines, or scientific instruments, the minimal stretch of polyurethane belts is a non-negotiable feature. If a small amount of position variation is acceptable, such as in a simple conveyor system, a rubber belt may be adequate.

-

Routing and Pulley Size: The flexibility of the belt is also crucial. For applications with complex routing, multiple bends, or small pulley diameters, the superior flexibility of rubber belts allows for easier installation and less stress on the belt. Polyurethane belts, being more rigid, are better suited for simpler, linear applications with larger pulley diameters.

Cost Considerations

While the initial purchase price is a factor, a comprehensive cost analysis should include long-term expenses.

-

Initial Cost: Rubber belts are almost always less expensive upfront. This makes them the preferred option for low-cost manufacturing and consumer products where cost is a primary design constraint.

-

Long-Term Maintenance and Lifespan: Polyurethane belts, despite their higher initial cost, often have a longer service life and require less maintenance due to their superior wear and chemical resistance. This can lead to lower total cost of ownership over the life of the machine, especially in critical or high-wear applications where downtime is costly. Conversely, the need for more frequent replacement of a rubber belt in a demanding environment could make it more expensive in the long run.

Environmental Conditions

The operating environment can have a significant impact on a belt's performance and lifespan.

-

Temperature: If the belt will be exposed to extreme temperatures, particularly high heat as found in engine compartments, an HNBR rubber belt is the ideal choice due to its wide operating temperature range. For applications operating at typical ambient temperatures, both materials are suitable, but it is important to check the specific temperature rating of the belt.

-

Chemical Exposure: In environments with exposure to oils, greases, or aggressive cleaning agents, the excellent chemical resistance of polyurethane belts makes them a superior and more reliable option.

-

Abrasive Contaminants: For systems operating in dusty or dirty environments where the belt may be exposed to abrasive particles, the superior abrasion resistance of polyurethane belts will ensure a longer lifespan and reduce the risk of premature failure. In cleaner environments, rubber belts perform perfectly well.

Maintenance and Care

Proper maintenance and care are essential for maximizing the lifespan and ensuring the reliable performance of any timing belt, regardless of its material. While the fundamental principles of inspection are similar, there are nuances to consider for both rubber and polyurethane belts.

Rubber Timing Belts

The maintenance of rubber timing belts is focused on managing the effects of aging, wear, and environmental exposure.

-

Inspection Guidelines: Regular visual inspections are crucial. Technicians should look for signs of wear and damage, including:

-

Cracks or Brittleness: These are signs of age and degradation from ozone or UV exposure. Cracks often appear on the belt's backing or between the teeth.

-

Frayed Edges or Shedding: This indicates improper alignment, excessive tension, or abrasion against a housing.

-

Missing or Damaged Teeth: A clear sign of a worn belt that has lost its ability to mesh properly with the pulleys.

-

Glazed or Shiny Surfaces: This suggests slippage or a problem with the pulleys, which can lead to overheating and premature failure.

-

-

Tensioning: Correct tension is vital. A belt that is too tight can cause excessive wear on the belt and bearings, while a belt that is too loose can slip, leading to timing errors and power loss. Always follow the manufacturer's recommended tensioning procedure, often involving a tension gauge.

-

Replacement Intervals: Due to the aging effects of rubber, these belts typically have a recommended replacement interval, often specified by the equipment manufacturer (e.g., every 5 years or 100,000 miles for automotive applications). It is critical to adhere to these guidelines, as a catastrophic failure of a timing belt can lead to severe and costly damage to the equipment.

Polyurethane Timing Belts

Maintenance for polyurethane timing belts is more focused on ensuring proper alignment and managing the specific wear patterns associated with their material properties.

-

Inspection Guidelines: Although more durable, these belts are not immune to wear. Key inspection points include:

-

Wear on the Teeth or Cord: Look for signs of abrasion or wear on the teeth, which could indicate misalignment. The steel or Kevlar cords, while strong, can be damaged by side loads or improper pulley alignment.

-

Discoloration or Surface Damage: While polyurethane is chemical-resistant, exposure to certain aggressive substances or extreme temperatures can cause discoloration or softening.

-

Splice Integrity: For open-ended belts that have been welded into an endless loop, the integrity of the splice should be checked to ensure it has not separated or been compromised.

-

-

Tensioning: Similar to rubber belts, maintaining the correct tension is paramount. Given their low elongation, it is even more critical to avoid over-tensioning, as this can put significant stress on the bearings.

-

Replacement Intervals: Polyurethane timing belts typically have a longer service life than rubber belts due to their superior wear resistance and resistance to aging. Replacement is usually based on a "condition-based" approach rather than a fixed interval. Belts are replaced when they show visible signs of wear or damage, allowing them to be used for their full service life. This reduces waste and maintenance costs over time.

For both types of belts, it is also important to ensure the operating environment is as clean as possible, and that pulleys and sprockets are in good condition and properly aligned. Debris, misaligned components, and worn pulleys can significantly shorten a belt's life, regardless of its material.

Future Trends and Innovations

The timing belt industry is a dynamic field, constantly evolving to meet the demands of new technologies and stricter performance standards. While the core function of timing belts remains the same, advancements in materials and the integration of "smart" technology are shaping the future of both rubber and polyurethane belts.

Advancements in Materials and Manufacturing

Manufacturers are continuously innovating to enhance the properties of timing belt materials.

-

Next-Generation Composites: The trend is towards using advanced composites to create belts with improved tensile strength, flexibility, and resistance to environmental factors. For rubber belts, this means new formulations of HNBR and other elastomers, along with the use of more advanced reinforcement cords like aramid or carbon fiber to increase strength and reduce stretch.

-

Specialized Polyurethane Formulations: For polyurethane belts, innovations are focused on creating specialized formulations that can withstand higher temperatures or offer better resistance to specific chemicals. This includes the development of ester-based polyurethanes with enhanced hydrolysis resistance and ether-based polyurethanes with improved strength.

-

Belt-in-Oil Technology: A major trend in the automotive industry is the use of "belt-in-oil" (BIO) systems, where timing belts operate submerged in engine oil. This technology, pioneered by manufacturers like Ford, reduces friction, improves quietness, and extends belt life. It requires specialized rubber compounds that can withstand constant exposure to hot oil.

Smart Timing Belts with Sensors

The integration of smart technology is set to revolutionize the timing belt market, particularly in industrial automation and precision applications.

-

Integrated Sensors: The next generation of timing belts may incorporate embedded sensors, such as strain gauges or temperature sensors, directly into the belt's structure. These sensors would provide real-time data on the belt's tension, temperature, and wear level.

-

Predictive Maintenance: By continuously monitoring the belt's condition, these "smart" belts would enable predictive maintenance. Instead of relying on fixed replacement intervals or visual inspections, a system could alert maintenance personnel to replace a belt only when it is actually nearing the end of its service life. This would minimize downtime, prevent catastrophic failures, and optimize maintenance schedules.

-

IoT and Data Analytics: Data from smart belts could be integrated into a plant's Industrial Internet of Things (IIoT) ecosystem. Advanced analytics could then be used to identify trends, optimize machine performance, and even predict potential issues before they occur.

While the rise of electric vehicles will reduce the demand for timing belts in new passenger cars, the vast installed base of internal combustion engines and the continuous growth of industrial automation, robotics, and high-precision machinery will ensure a strong and evolving market for both rubber and polyurethane timing belts for the foreseeable future.

English

English 中文简体

中文简体